While working with the SolidWorks assembly can perform joint processing of multiple parts, program processing a series of parts, or just completely simulate all the real situation on the machine table - all of snap, logging of any complexity, and so on - for the most complete account the realities of treatment at the earliest stages New Programġ.

Detail can be easily adapted to the needs of processing by, for example, to eliminate redundant terms of processing elements of the geometry or by applying to the executive model dimensions in the middle of the tolerance. When added to the SolidWorks model of any process data, such as signs of roughness, base tolerances of form and arrangement of surfaces, tolerances on dimensions, engineer-programmer always has immediate access to them, which facilitates the selection scheme based on machine parts and selection of required ensure the specified quality parts of the tool and cutting conditions. This provides full associativity of the model and tool path that leads to the automatic renewal of the tool path when the model changes. The results of the programmer are stored in the same model part or assembly SolidWorks.

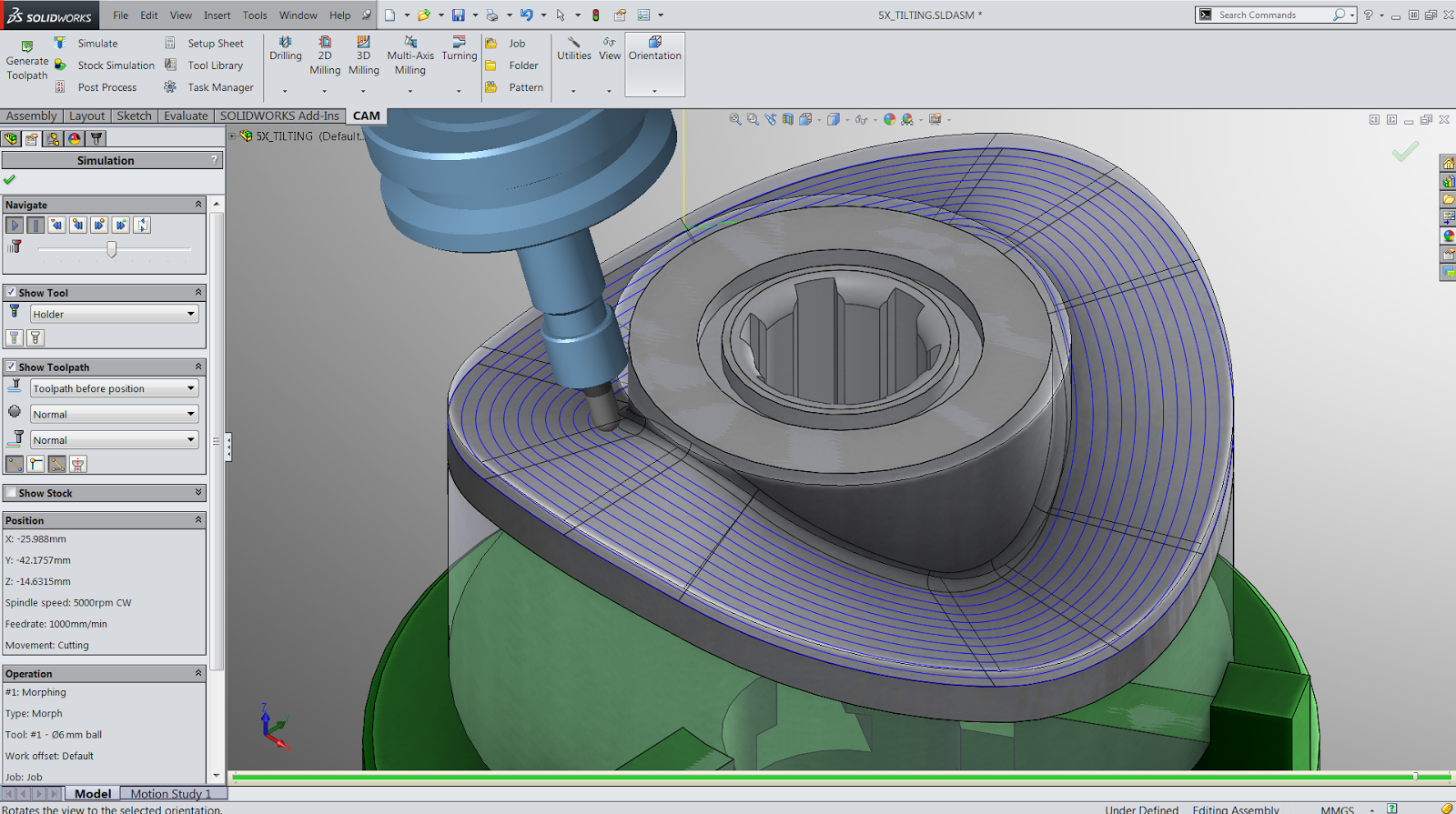

Treatment is carried out directly in SolidWorks and directly on the model of SolidWorks. * Turning and Milling single and duplex, with one or two slides, with a programmable servo- mechanism, with simultaneous control of two? five axles * Turning single and duplex, with one or two slides, with a programmable servo -mechanism (tailstocks, lunettes, catcher details. The following types of machines: milling with simultaneous control of two ? five axles

* Module CAMWorks allows you to create programs milling, turning, turning, milling and wire EDM. Programming milling, turning, turning, milling and wire EDM module means CAMWorks. Camworks 2014 Sp1.0 Multilanguage (x86/圆4) | 2.24 GBĭescription : CAM (Computer Aided Manufacturing) Works a module for creating control programs for CNC machine tools.

0 kommentar(er)

0 kommentar(er)